Background

Concrete surfaces are always a "mirror image" of your formwork, since this is essentially responsible for the surface quality. The contact of the fresh concrete with the formwork skin results in an air void on the concrete surface or in the areas near the surface of the concrete. The resulting pores or cavities, as well as small cavities on the surfaces of the concrete are often complained of defects in construction practice.

Technical Description

With the technology of a porous formwork skin, through which water and air can penetrate but which is impermeable to the cement paste, the above-mentioned structural defects can be avoided. The great and also financial advantage of the technology lies in the fact that concrete with low-porosity surfaces does not have to be optimized via the concrete formula, as has been customary up to now. In addition, there are other advantages due to general material savings, as the formwork is easy to clean and can therefore be easily reused.

Possible Applications

The production of concrete formwork with high surface quality requirements, e.g. in the area of exposed concrete, is possible with this invention.

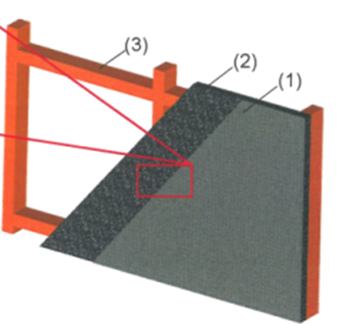

Structure of the formwork skin; (1) Microporous membrane; (2) Porous carrier layer, preferably of metal, (3) Substructure