Background

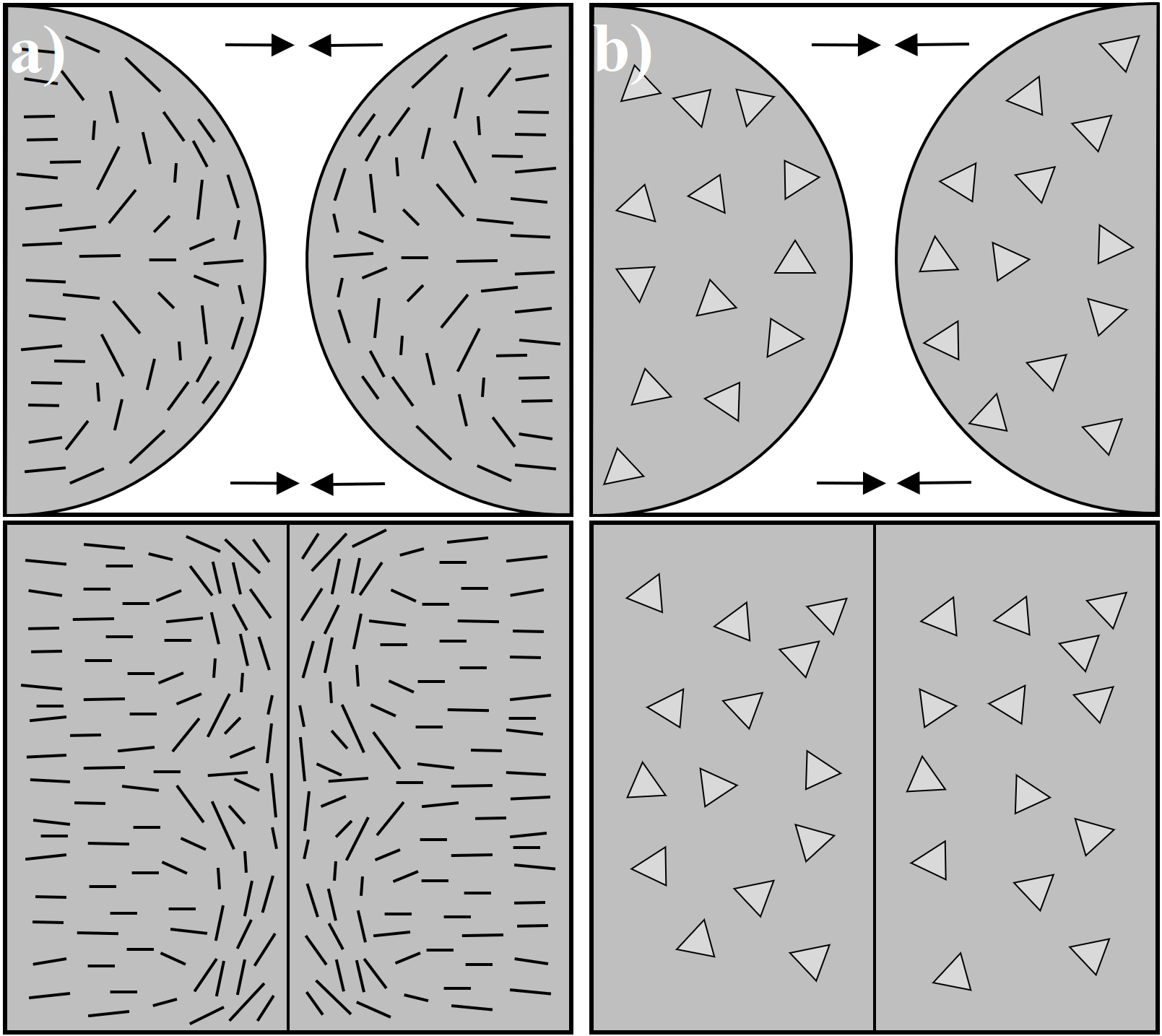

Filling polymers with metal effect pigments is a key technology to achieve metallic appearances of injection moulded polymer parts while avoiding additional coating steps. Conventionally, metallic appearance is generated due to the orientation of planar metal effect pigment particles in the flow direction of the polymer melt, usually parallel to the part surface in order to reflect light to the viewer. Nevertheless, where polymer fronts merge, the particle orientation is disturbed (Fig. 1), resulting in locally enhanced light scattering and thus creating dark streaks in the solidified polymer part, called flow lines.

Technical Description

The invention presented here solves this problem by introducing novel pigment particle geometries, preferably such as tetrahedrons, pyramids and cubes. By the geometry, the degree of parallel particle orientation can be regulated and the flow line visibility reduced (Fig. 2). Moreover, the degree of the flop can be regulated. There are broad varieties of possible manufacturing methods of the novel metal effect pigments such as cold forming, rolling, pressing, molding, and machining. The pigments, consisting of aluminium, copper, brass or coated polymer, can be used in common polymer processing, such as injection molding and extrusion.

Possible Applications

Colouring of plastics to achieve metallic apperarance.

Figure 1: Schematic representatin of the pigment orientation of a) conventional platelet particles and b) novel tetrahedral particles.