Background

Stents are small tubes or tubular shaped meshes which are used to keep or rebuild the luminal size of passages in the human body such as coronary arteries and the oesophagus. Most commonly stents are used in the treatment of stenosis (narrowing of the blood vessels). They can be utilized as implants or in conjunction with an angioplasty (a technique for widening narrowed arteries). The most common complications when using stents are in-stent restenosis and stent loss. In-stent restenosis is the re-narrowing of the implanted stent which occurs in ~30 % of all cases.

Technical Description

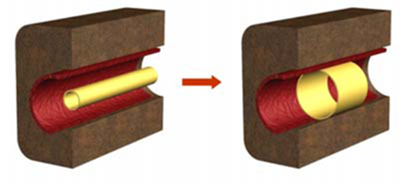

To prevent restenosis, drug eluting stents have been developed. This has been a success to a certain extent, but a big problem of drug eluting stents are the late effects, such as the increased risk of bleeding, acute intoxication and the formation of tumors. The microstructured polymer stents according to this invention are made of a shape memory polymer (e.g. polyurethane). Below body temperature, the shape memory polymer stent has a compressed geometry (temporary form). When heated to body temperature, the shape memory polymer stent assumes an uncompressed geometry (its predefined permanent form). Since the inner surface of the stent is microstructured, it limits laminar flows and thus prevents in-stent restenosis. The outer surface is structured (e.g. microporous), which results in a fixation of the stent and thereby prevents the stent to get lost. Therefore, the polymer stent is a reliable device for angioplasty procedures. The structure of the polymer surface can be achieved with different methods, e.g. via molding, laser structuring or etching.

Possible Applications

Pharmaceuticals, Medical Devices

Schematic illustration of a shape memory polymer stent in the compressed temporary state (left) and the uncompressed permanent state (right)