Background

The performance of aromatic polyethers in numerous applications relies largely on the combination of bulk properties together with the aromatic polyether-based materials surface properties. However, these materials have limitations associated with mechanical stress, cracking in certain solvents, poor tracking resistance, and weathering properties. Chemical modifications of commercially available aromatic polyethers may be performed by a certain polymer modification (functionalization). Most of the methods for such modifications of an aromatic polyether backbone require careful selection and optimization of reaction conditions, solvents, and modification reagents to avoid undesirable side reactions, like crosslinking of polymer chains and chain fission reactions, since they lead to the most severe change in the consumer properties of the modified polymer.

Thus, there is a persistent need to develop new processes for large scale chemical modification of polymers, which would consider and minimize the cost of the modification process, as well as minimize its negative impact on the environment.

Technical Description

The present invention relates to a process for modifying / functionalizing a polyether polysulfone backbone, and to a modified functionalized polymer obtained in this process. This new method relates to an improved, economical and environmentally friendlier method resulting in a modified polymer with improved consumer properties. The process is simplified in terms of time requirements and complexity as compared to previously used methods.

Possible Applications

Aromatic polyethers are attractive polymer materials for a range of applications, such as separation membranes, which have been developed for a wide variety of applications, e.g. in separation technology, biological processes, medical devices, and blood purification. In addition, due to superior thermal, chemical, and mechanical properties of aromatic polyethers, they are widely used as filtration membranes, coatings, composites or in microelectronic devices, and fuel cells.

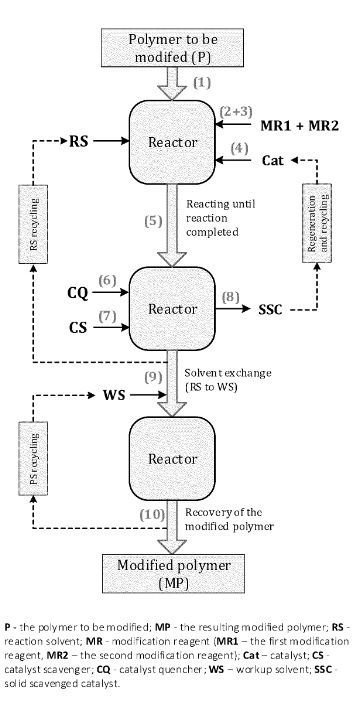

process example (© TU Berlin)